Metalwork Machinery (Wuxi) Co., LTd., was established in 2006,

specializing in cutting and welding automation manufacture, sales,

and services with more than 10 years experience.

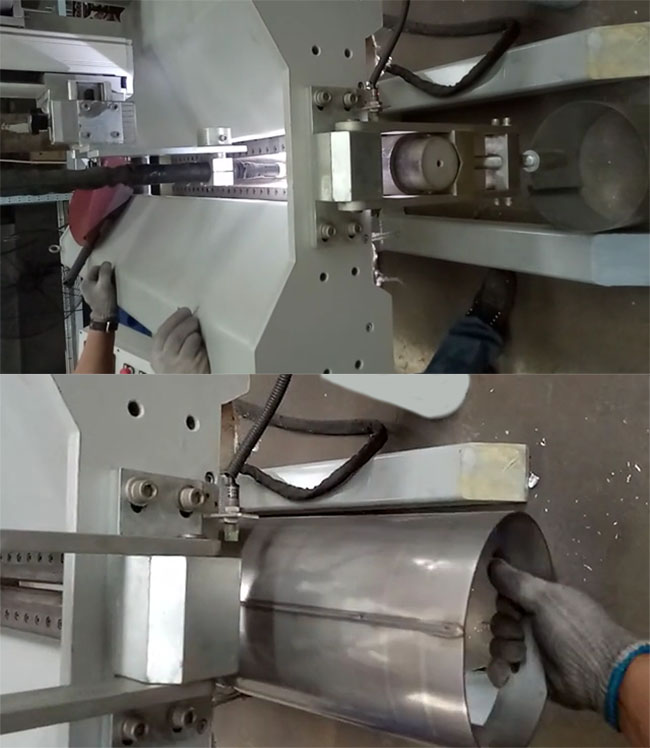

Our products ranges: CNC flame and plasma cutting machine, CNC

fiber laser cutting machine, arc welding machine, automatic

resistance welding machine, automatic seam welding machine, H beam

and box beam production line, robotics welding and cutting

stations, etc. We also can produce the customized machine

according to customer's workpiece.

Moreover, we are specialized in "whole solution" of production

lines for our customers, we not only supply you the individual

equipment, but also delivery a solution for your project. This will

bring you more values from us.

With regard to the welding equipment industry, advanced technical

well-know in design and production activities and long term

experience, we provide important technology and innovations for

tank, pressure vessel, boiler,ship building, nuclear power,

electric power station, manufacturing processes. We not only sell

the equipment, but also delivery value to customers.

Service is our specialty, after long time cooperation, you will

satisfy more with us.

If you have any queries, please do not hesitate to contact us by

phone or E-mail. We will revert to your questions, within 24 hours

after your requests.

Nearby locations:

PVG Pudong airport, 178Km, by train: 50 min

Wuxi Airport: 35Km, by car: 50 min

Peking Airport: 1100Km to Wuxi, 2hrs by plane

Shanghai Port: 145Km, 2hrs by truck

Wuxi Railway Station: 25Km, 40 min by car